CONSTRUCTION

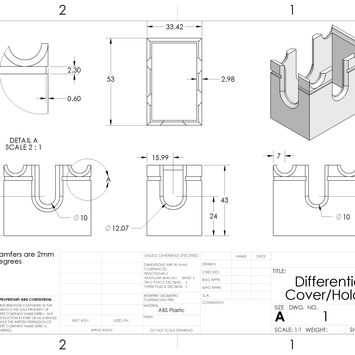

The motor mount/transmission as well as the main differential components are manufactured of abs thermoplastic using a 3D printing process. The parts are modeled in SolidWorks in accordance with the restraints placed by the printer. The steering rod is machined from 6061 aluminum flat bar stock and machined with the manual mill and drill press. With one hole in the middle of the bar and one on the servo wheel, a pin loosely mates with the two. Having the pin loose, allows for the steering rod to move back and forth without binding. A major change that was implemented during the construction phase of the project was the separation of the differential housing from one to two parts. The differential was split into two halves with slots that interlock when they are placed together. To facilitate this change, the differential cover design was changed also to include an exterior set of walls with cutouts where the shafts enter and exit the housing ne to two parts. The remaining parts were purchased.

The drivetrain consists of four major components that are fabricated using the available equipment at the CWU MET department. These parts were all printed from ABS plastic using the rapid prototype machine. Assembly can be seen below.

•Transmission Housing (Item No. 1)

•Differential Case (Item No. 12)

•Differential Housing Left & Right (Item No. 8 & 9)

•Differential Cover (Item No. 17)

|  |  |  |

|---|---|---|---|

|